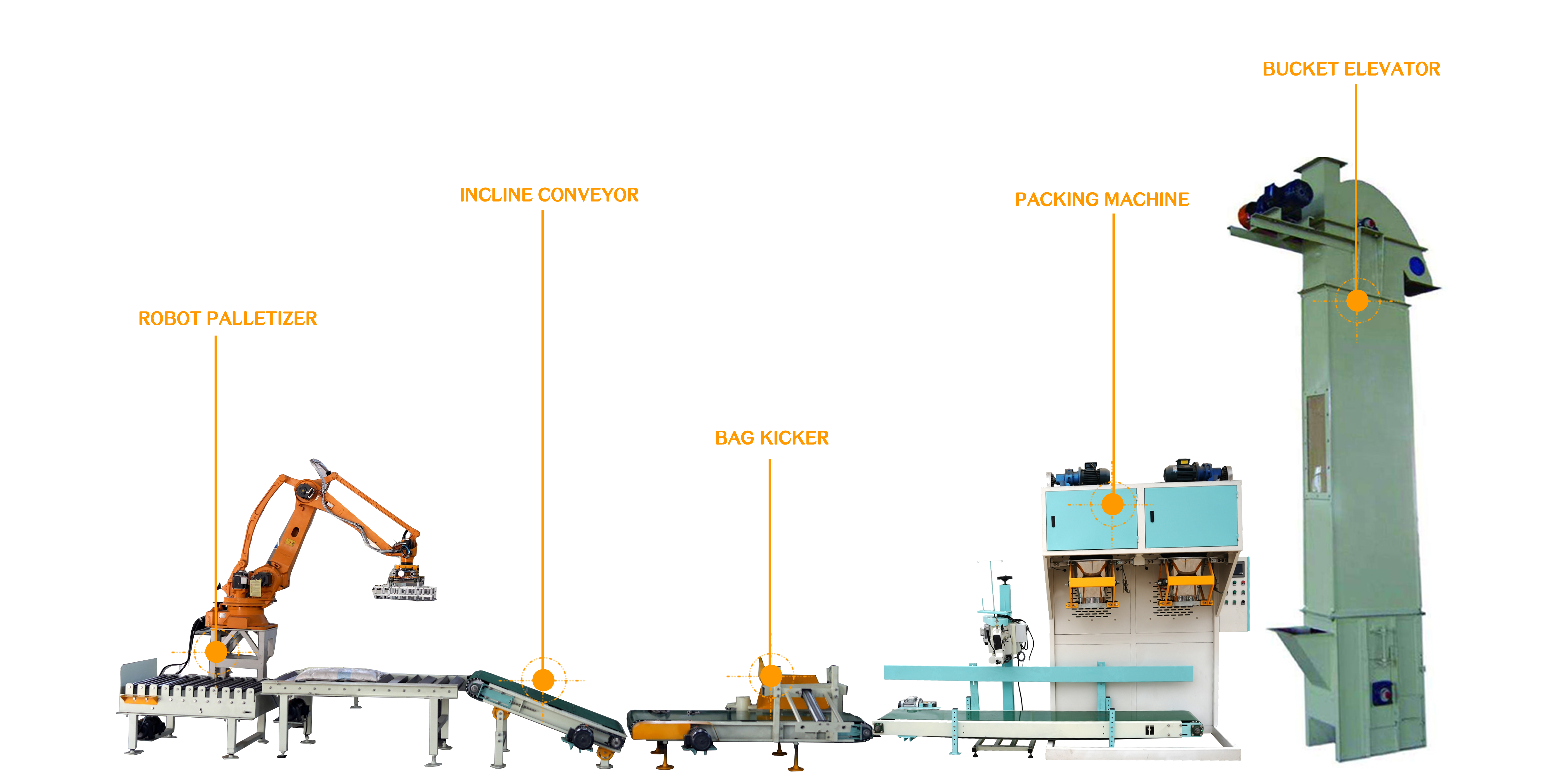

Automatic bag holding machine

Classification

Detailed introduction

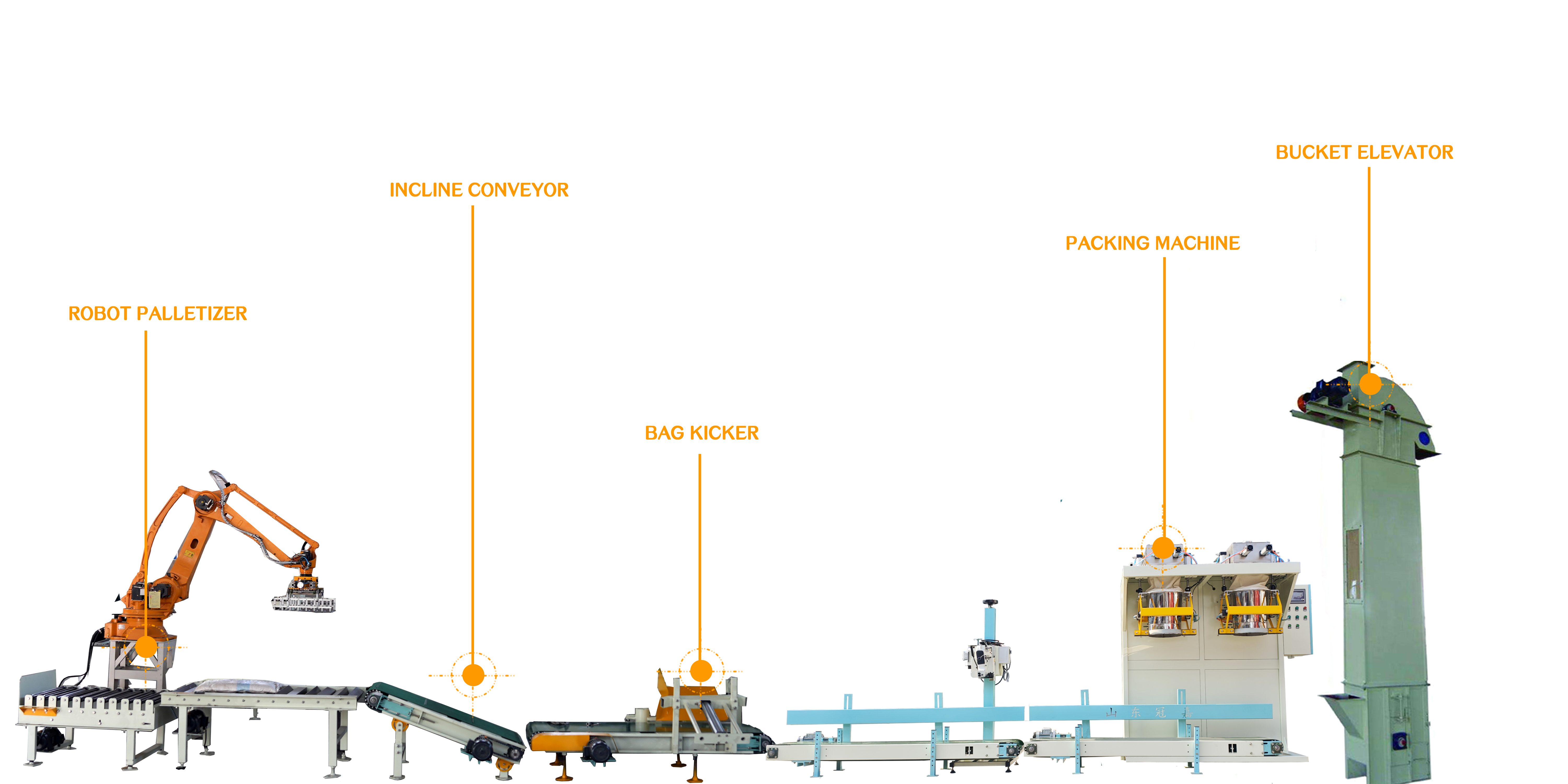

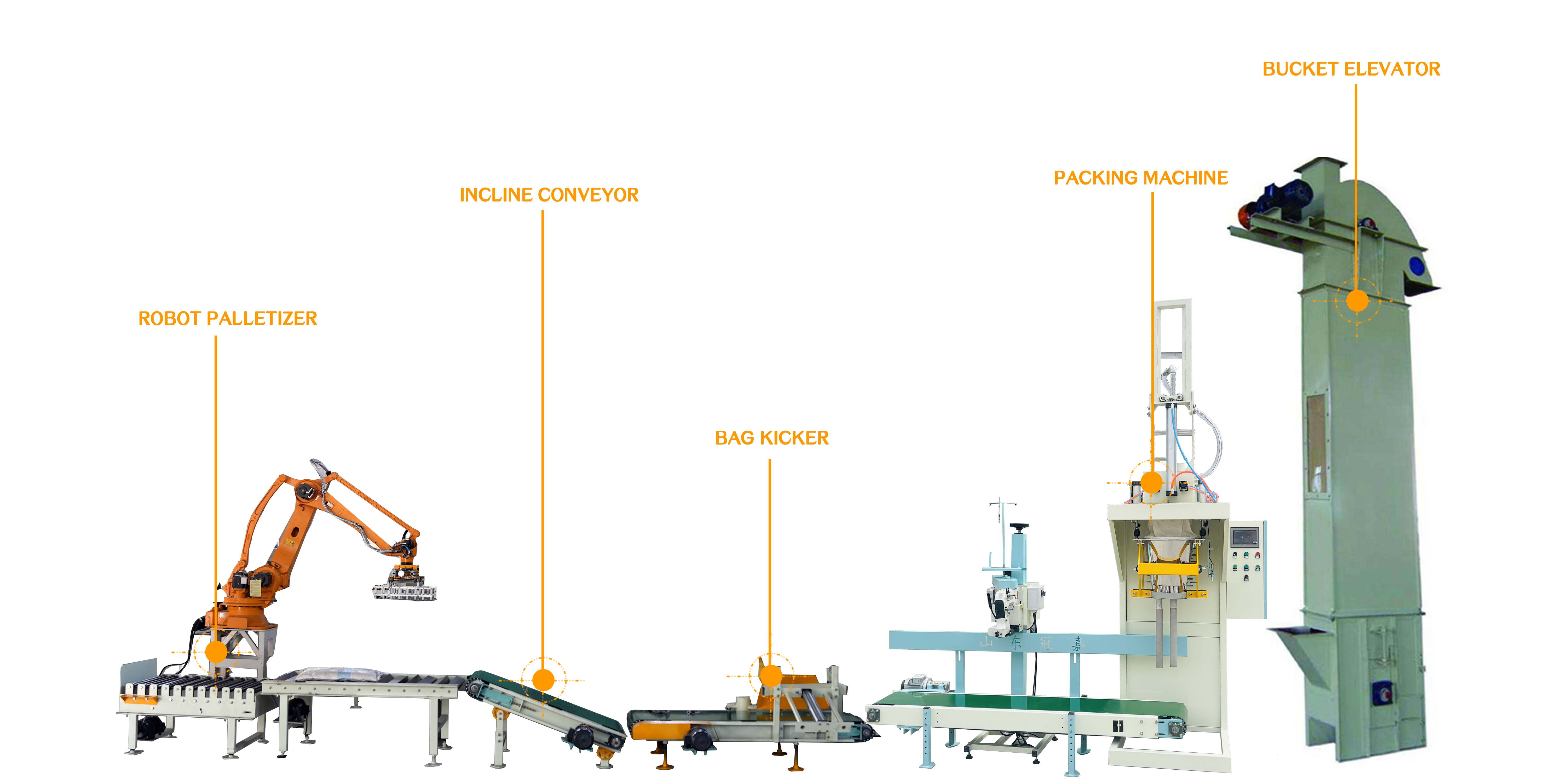

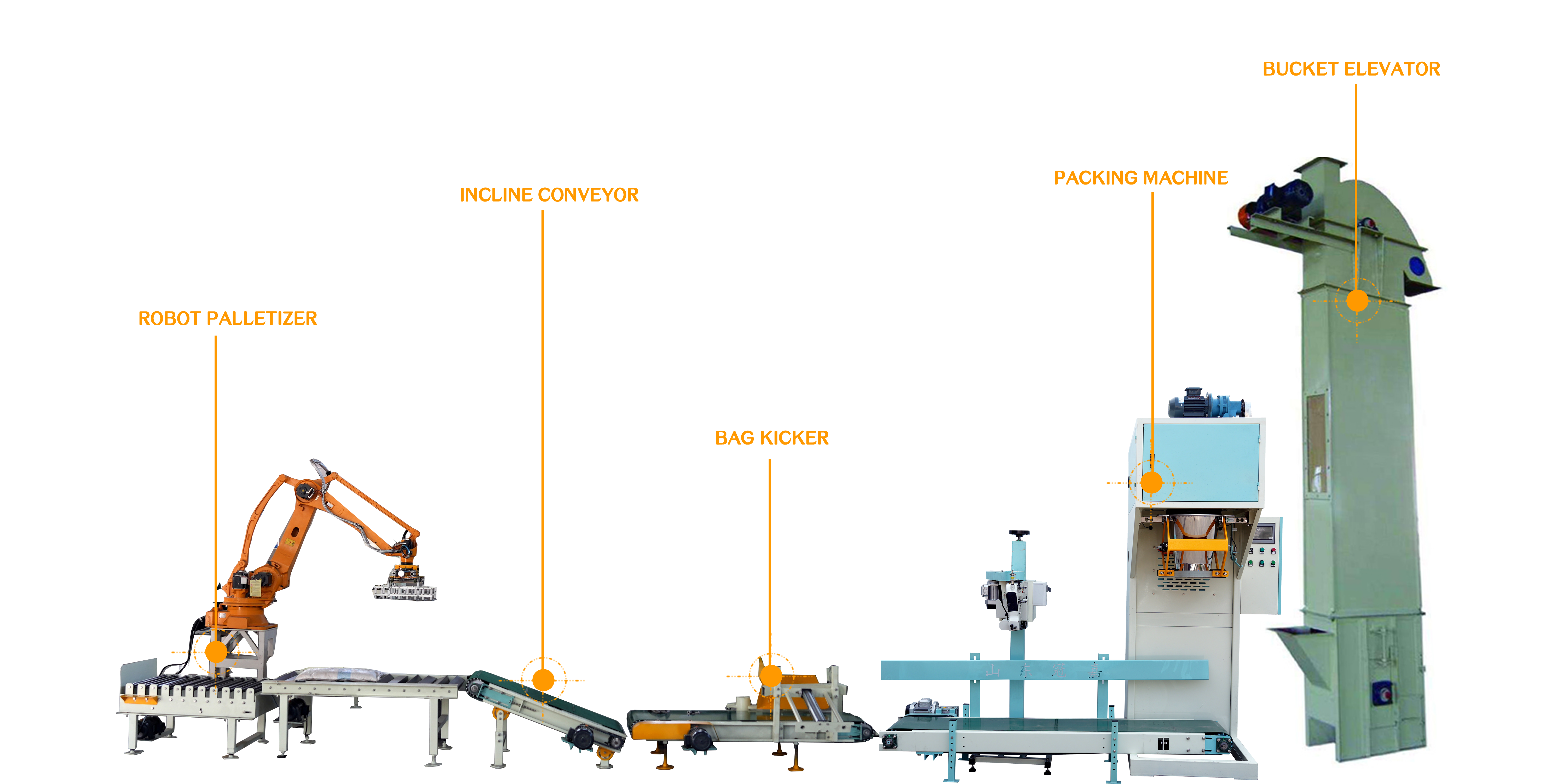

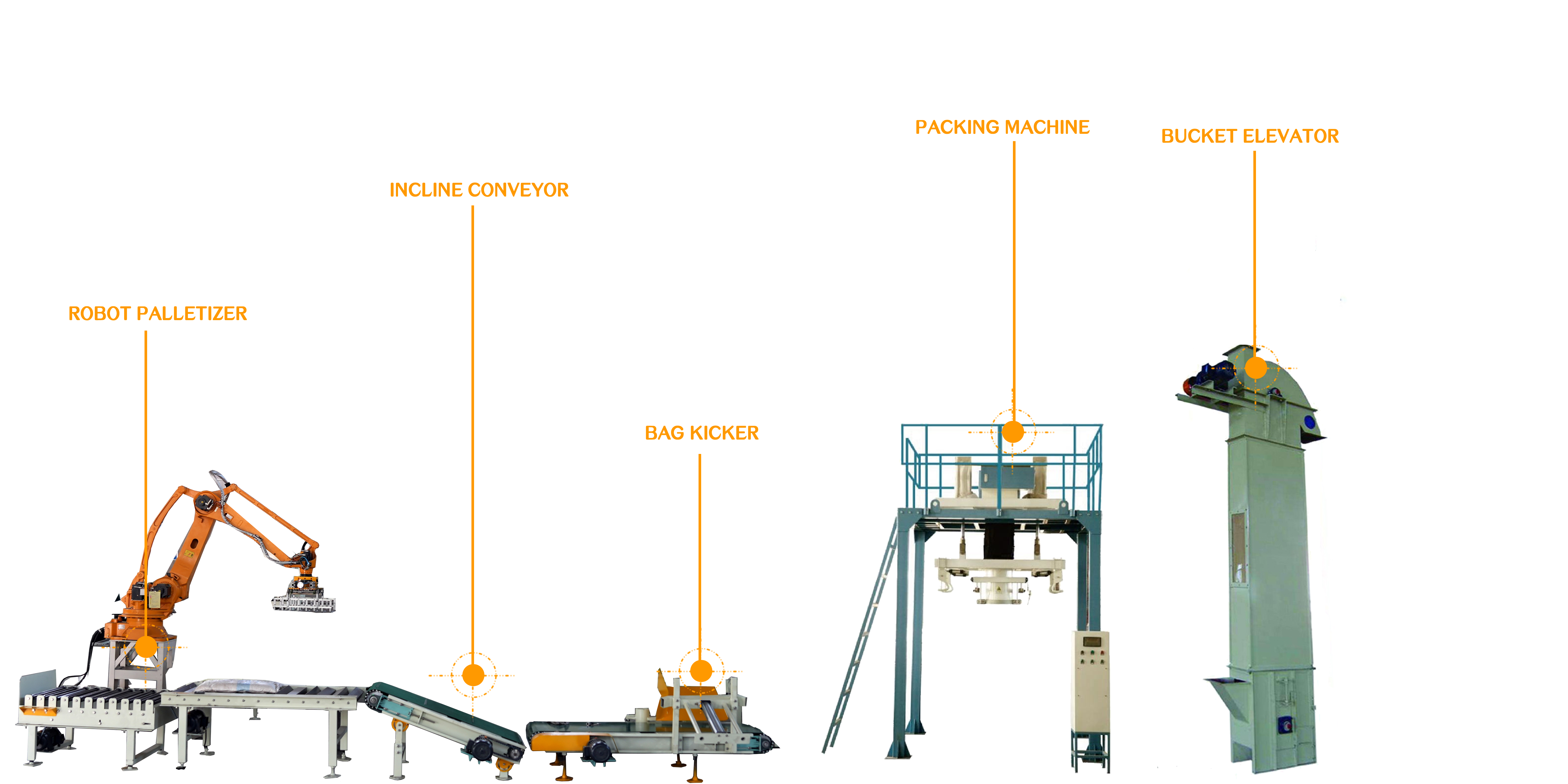

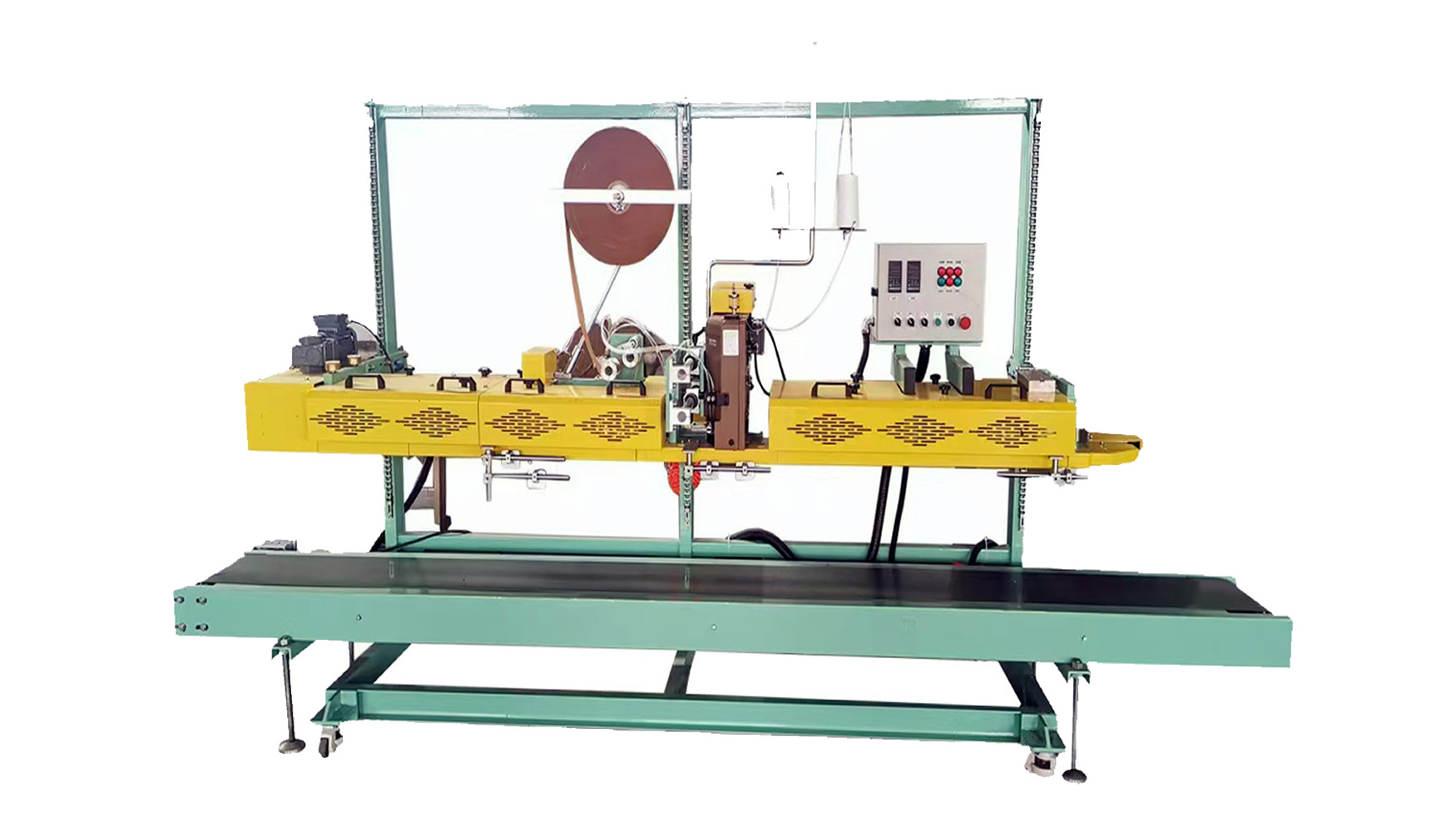

Equipment description:

Lateral movement of solid bag and bag clamping lead-in device →

The solid bag is placed on the vertical bag conveyor from the blanking port, and the bag mouth is held by the bag mouth holding device and transported to the sealing part.

Vertical bag conveyor →

The solid bag is transported to the downstream at a constant speed by this conveyor, and the height adjustment handle can adjust the height of the conveyor.

Transition conveyor →

Docking with equipment of different heights.

Functional features:

The system can be applied to paper bags, woven bags, plastic bags and other packaging materials, the front end only need manual bagging, the back end without manual, automatic folding, sewing bag, optional automatic labeling machine. Mainly in the chemical industry, feed, fertilizer and other industries are widely used.

Can carry out 10kg ~ 50kg bag sewing bag, with a capacity of up to 600 bags/hour.

Automatic sewing device to adapt to high-speed continuous operation.

Each execution unit is equipped with control and safety devices to realize automatic continuous operation.

The equipment is controlled by PLC and operated by touch screen.

Automatic sewing machine automatic sewing bag, realize the whole process of full automation.

Docking with equipment of different heights.

Key words:

Related Products