The granule packaging machine production line is widely used in pharmaceutical, food, chemical and other fields, suitable for automated packaging of various granular products, such as drug granules, food granules, fertilizer granules, etc.

The granule packaging machine production line is suitable for automatic quantitative weighing and packaging of materials such as feed, fertilizers, corn, organic fertilizers, rice, seeds, etc.

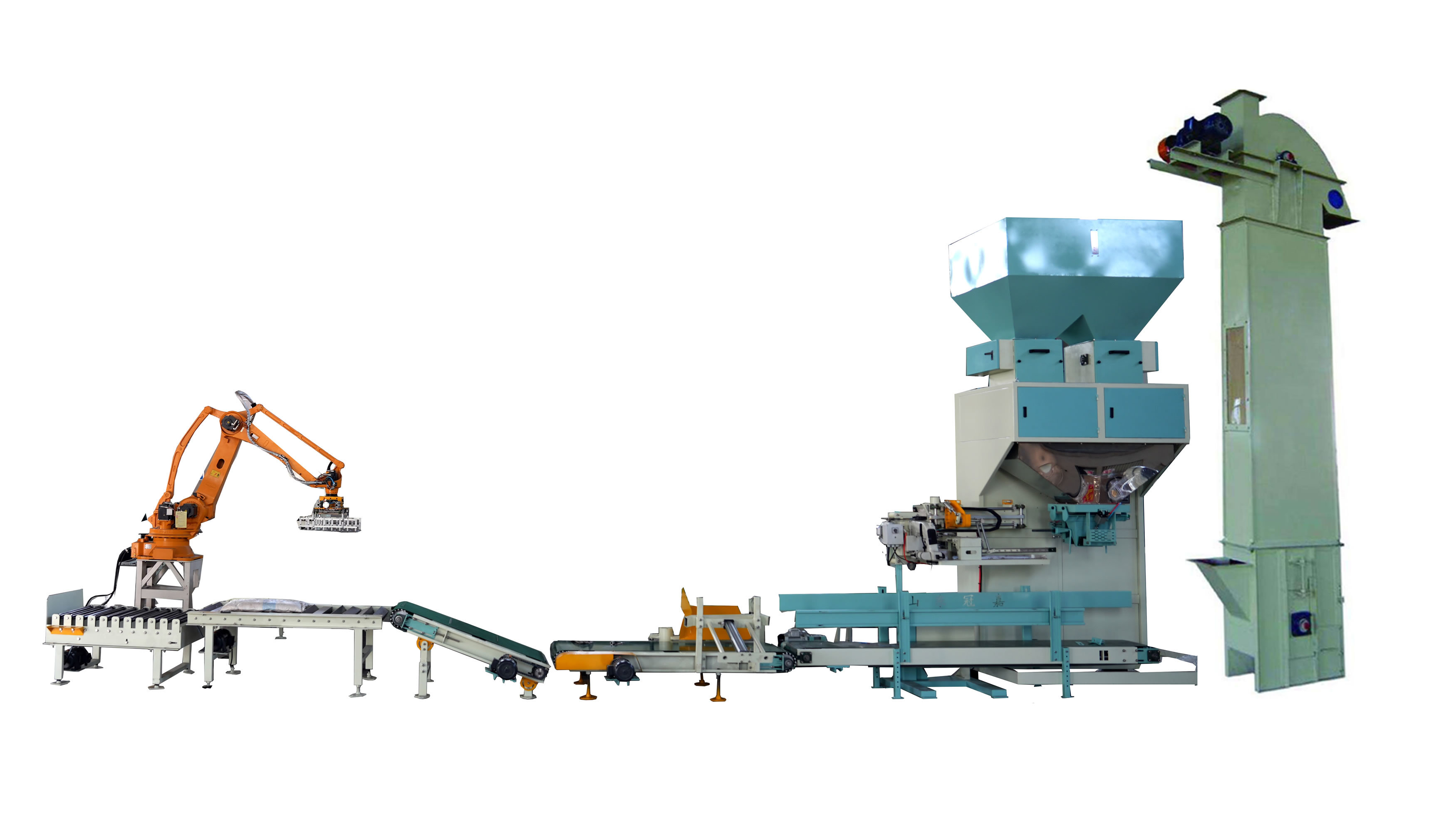

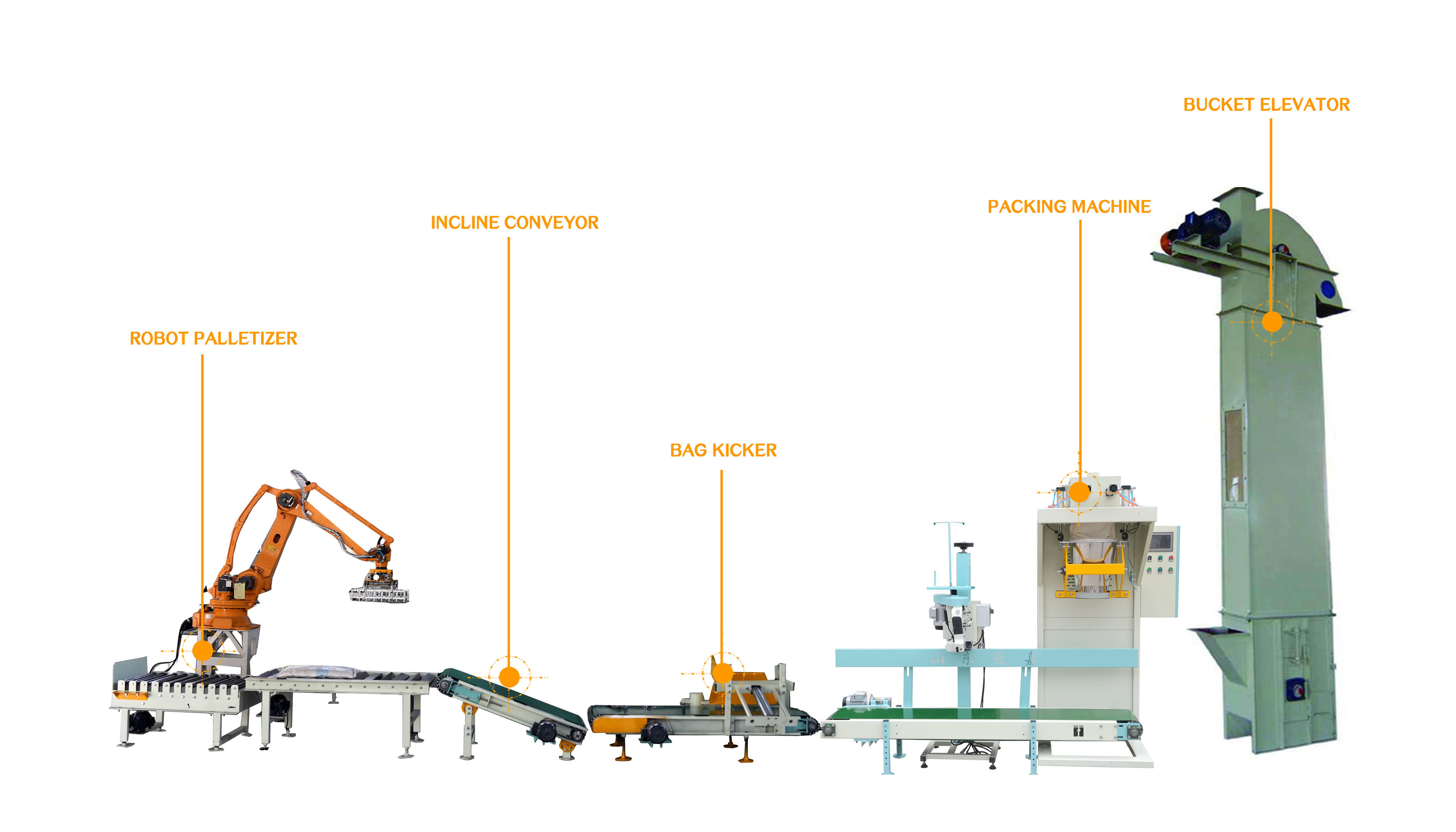

The packaging machine production line independently produced by Shandong Guanjia Intelligent Equipment Co., Ltd. mainly includes:

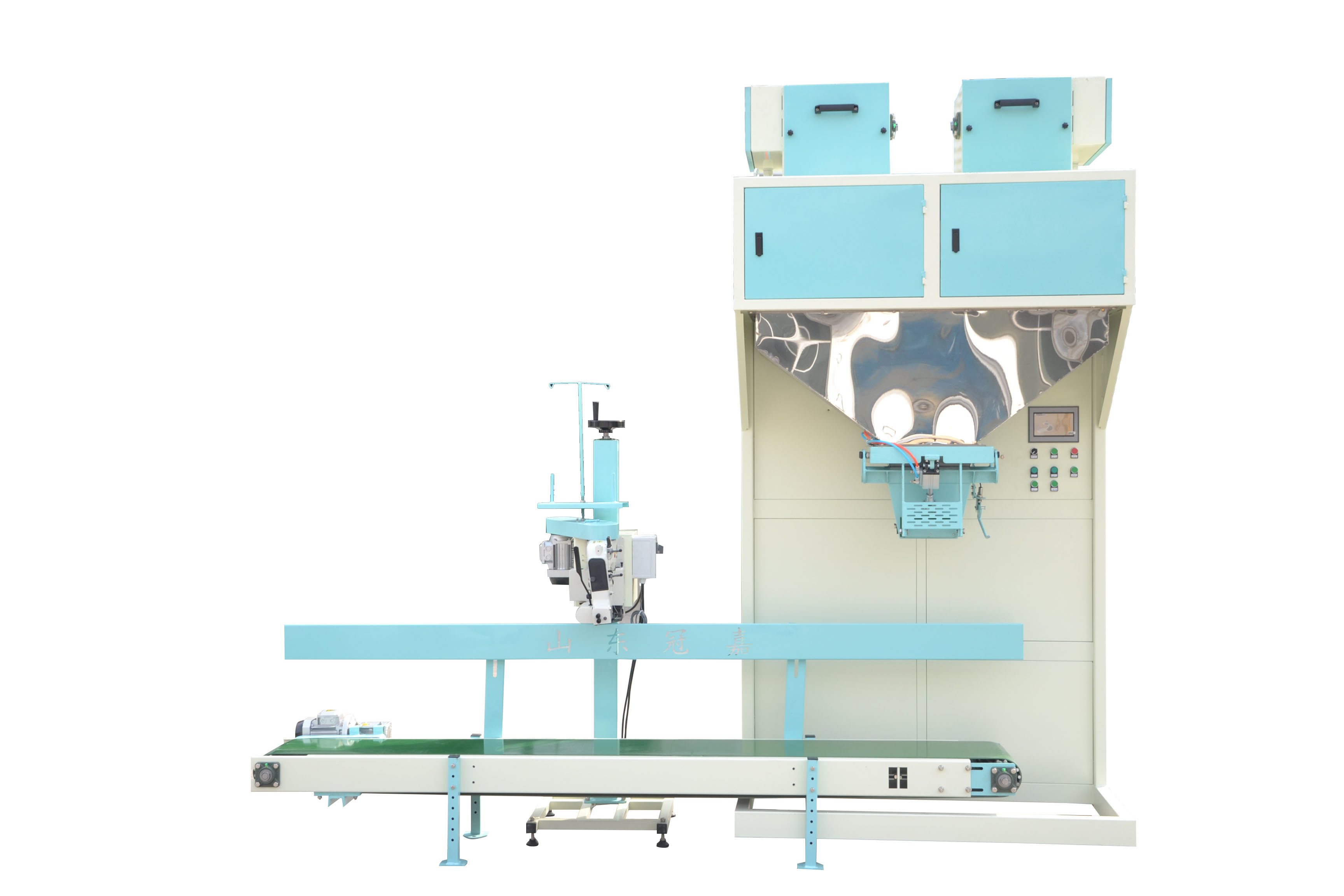

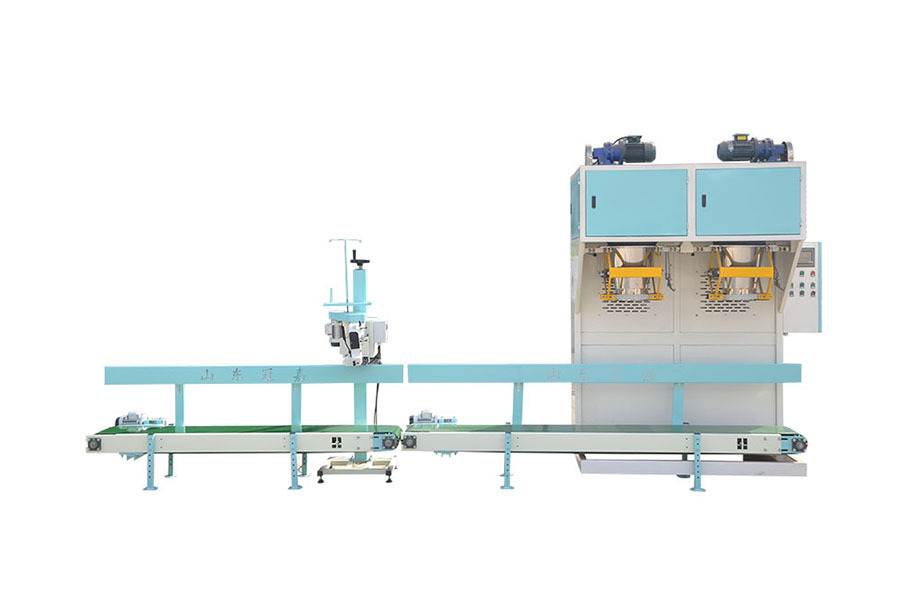

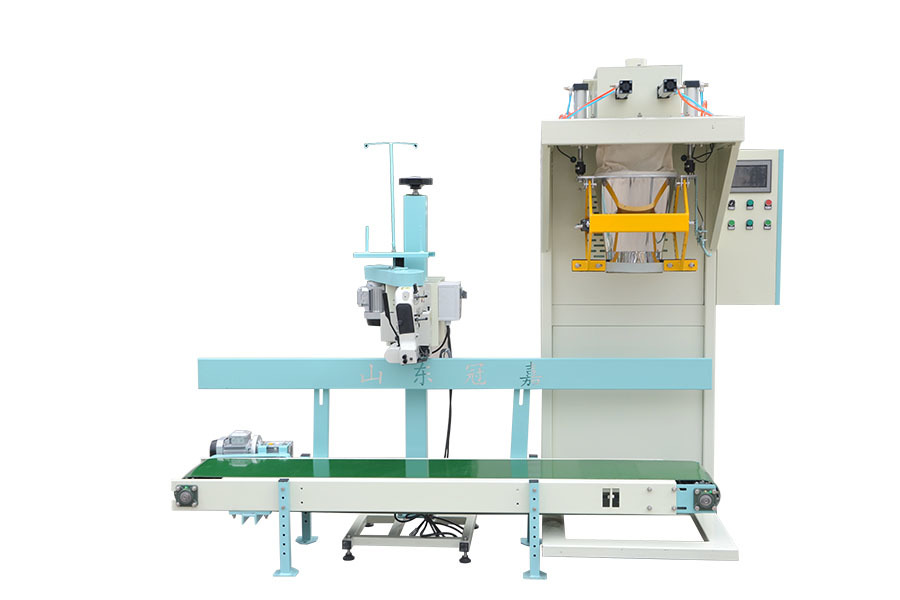

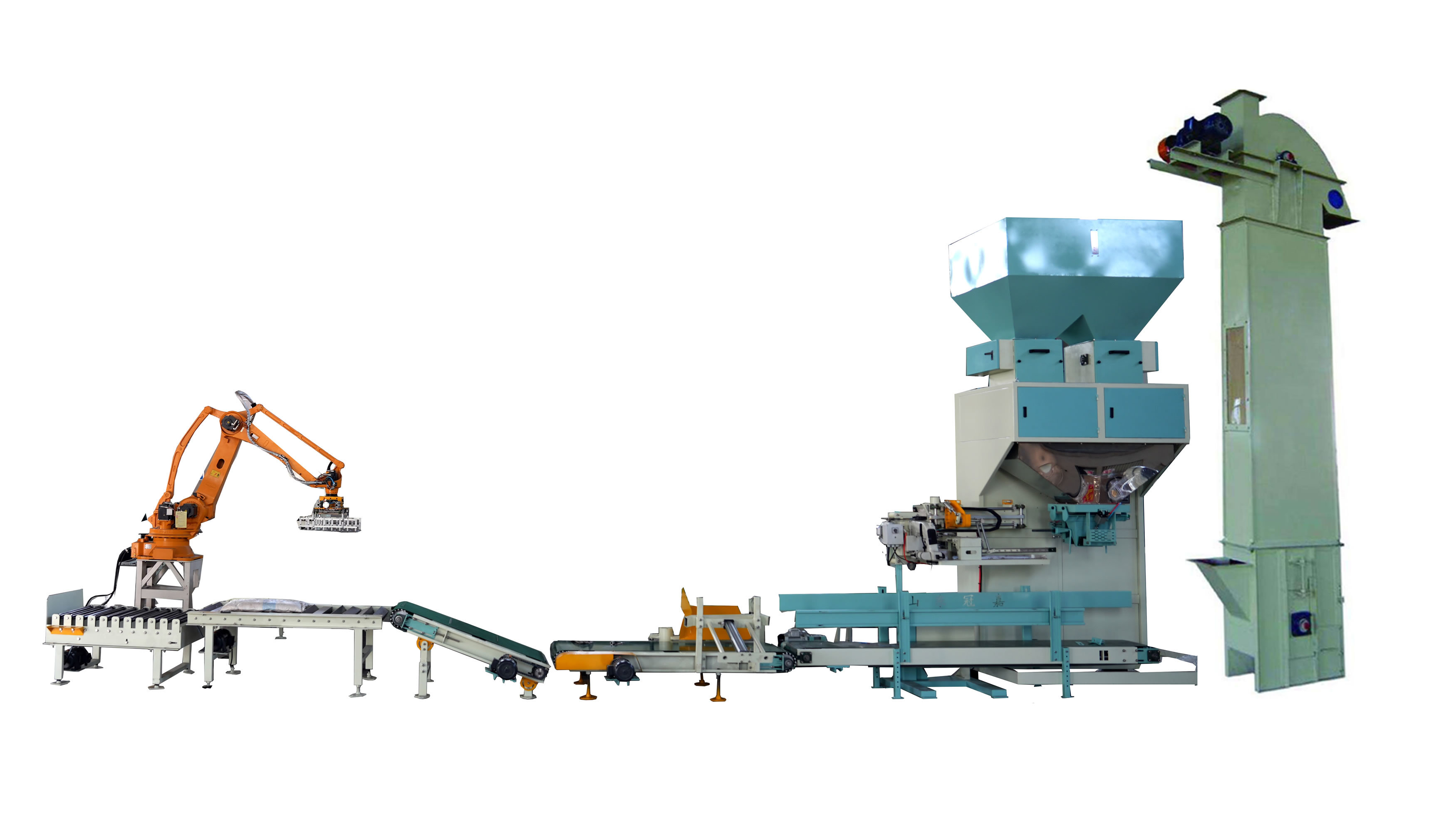

1. Packaging Machine Unit (including conveyor、sewing and control system)

2.Elevator (Optional:Vertical elevator and inclined elevators; Carbon steel and Stainless steel )

3.Bag kicker

4.incline conveyor

5.Bag flattner

6.Roller conveyor

7.Robot palletizer

The standard production line is shown, and the specific configuration will be designed separately according to the actual situation of the customer.

Customer Case

Muhammad A-sad munir is a customer from Saudi Arabia and is the world's leading manufacturer and supplier of chemical fertilizers and organic fertilizers. With years of experience, the Saudi Arabian company has become the ultimate expert in sustainable fertilizer production, supported by GuanJia Packaging Solutions.

A comprehensive partner for your packaging needs

Muhammad A-sad Munir has relied on GuanJia's expertise and stainless steel weighing filling machine for many years and uses them in its factories in Saudi Arabia. Muhammad A-sad munir was looking for a full-service partner to meet his packaging needs, and GuanJia provided a specialized set of specific recommendations while working with the client to find the most meticulous solution. Based on the requirements of Muhammad A-sad munir, we transform them into a full range of solutions that match their specific wishes and the fertilizer industry. According to the characteristics of fertilizer, we recommend choosing a stainless steel weighing filling machine with high degree of automation, fast speed, high packaging accuracy and anti-corrosion, so our recommended solution for Muhammad A-sad munir includes a granule stainless steel weighing filling machine and a palletizer, and The necessary conveyor belts are connected to the automated transport system for transporting the pallets directly to the warehouse, which saves labor to a large extent. At the same time, Muhammad A-sad Munir Company requires that the weight of each bag of fertilizer is 45kg/bag. The weighing range of GuanJia's granular stainless steel weighing filling machine is: 10kg-50kg, and the maximum weighing speed can reach: 400-700bag/h. This stainless steel weighing filling machine meets the requirements of partners to a great extent.

Productivity improvements

GuanJia aims to increase Muhammad A-sad munir’s fertilizer packaging production capacity. After surveying and analyzing the site conditions, GuanJia conducted different planning stages and in close consultation with the customer, designed a customized installation plan suitable for Muhammad A-sad Munir Company. Setting up the machine according to its specific bag, product, speed and situation, in addition to setting various parameters, we also pay great attention to the connection with other systems: communication with other machines, product supply, data systems, etc.

Packaging machine maintenance and care recommendations

In order to ensure the normal operation and extend the service life of the stainless steel weighing filling machine, it is recommended to develop a regular maintenance and upkeep plan. This includes cleaning equipment surfaces and internal parts, checking equipment wear, regularly changing lubricants, etc.

Get a Quote