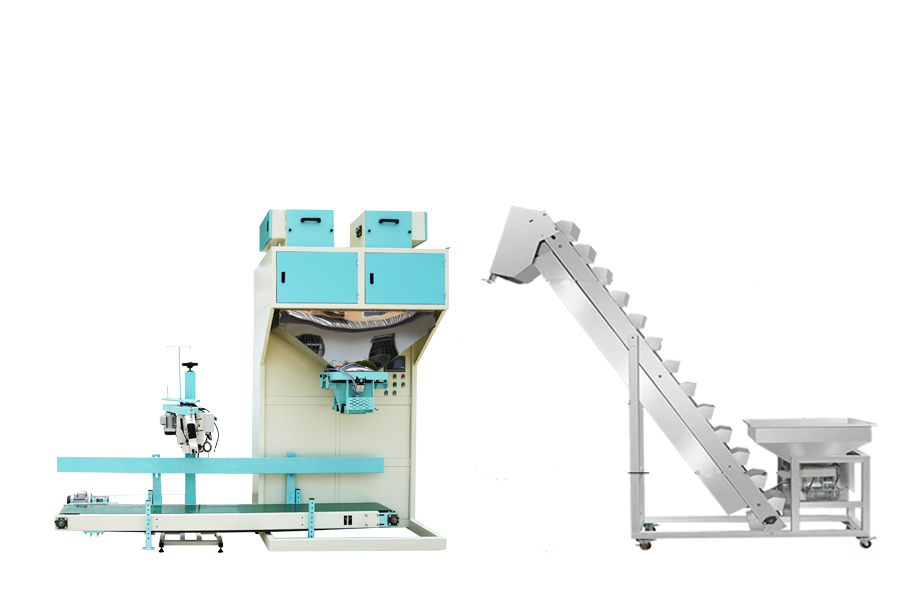

Double bucket type granule packing scaleDCS-ZQ-X-50

Classification

Detailed introduction

Scope of application:

Quantitative packaging of granular materials in grain, sugar, seeds, food industries, plastic granules, cat litter and so on.

Features:

There are two sets of weighing buckets in the scale. The AB bucket weighs and unloads materials in a cycle, which is faster.

Single button start, automatic blanking, real-time metering, three-speed feeding.

Solve the problems of packaging some special chemical raw materials, with wide application range and simple operation.

Using high-precision sensors and highly intelligent weighing controllers, the measurement accuracy is high and the performance is stable.

The parts in contact with the material are made of stainless steel with high corrosion resistance.

Electrical and pneumatic components are imported components with long service life and high stability.

The control cabinet adopts a sealed form and is suitable for harsh dust environments.

Automatic correction of material out-of-tolerance, automatic zero tracking, overshoot detection and suppression, over and under quantity alarms.

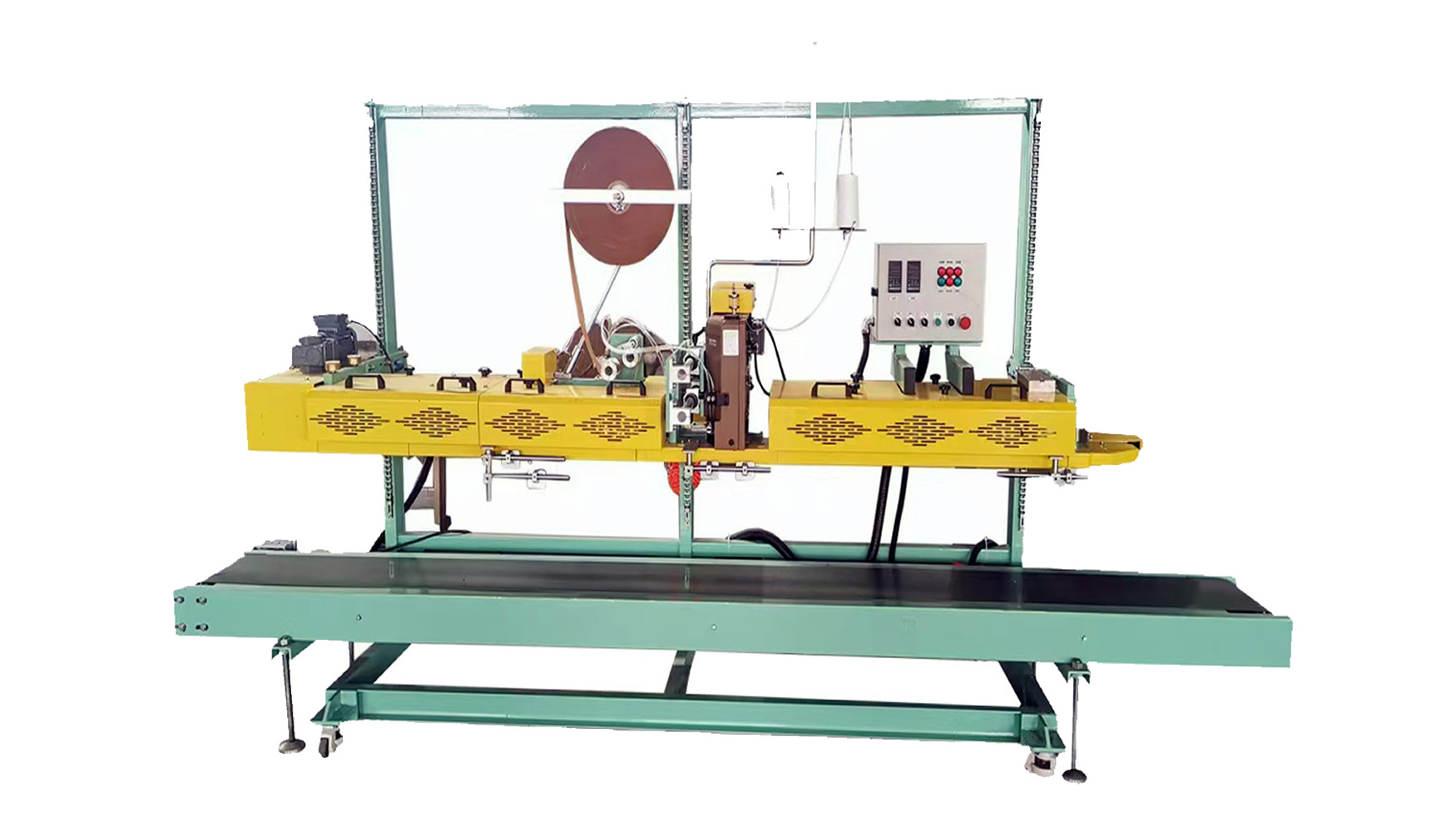

Equipped with automatic sewing thread cutting function: photoelectric induction automatic pneumatic thread cutting after sewing bags.

Technical parameters:

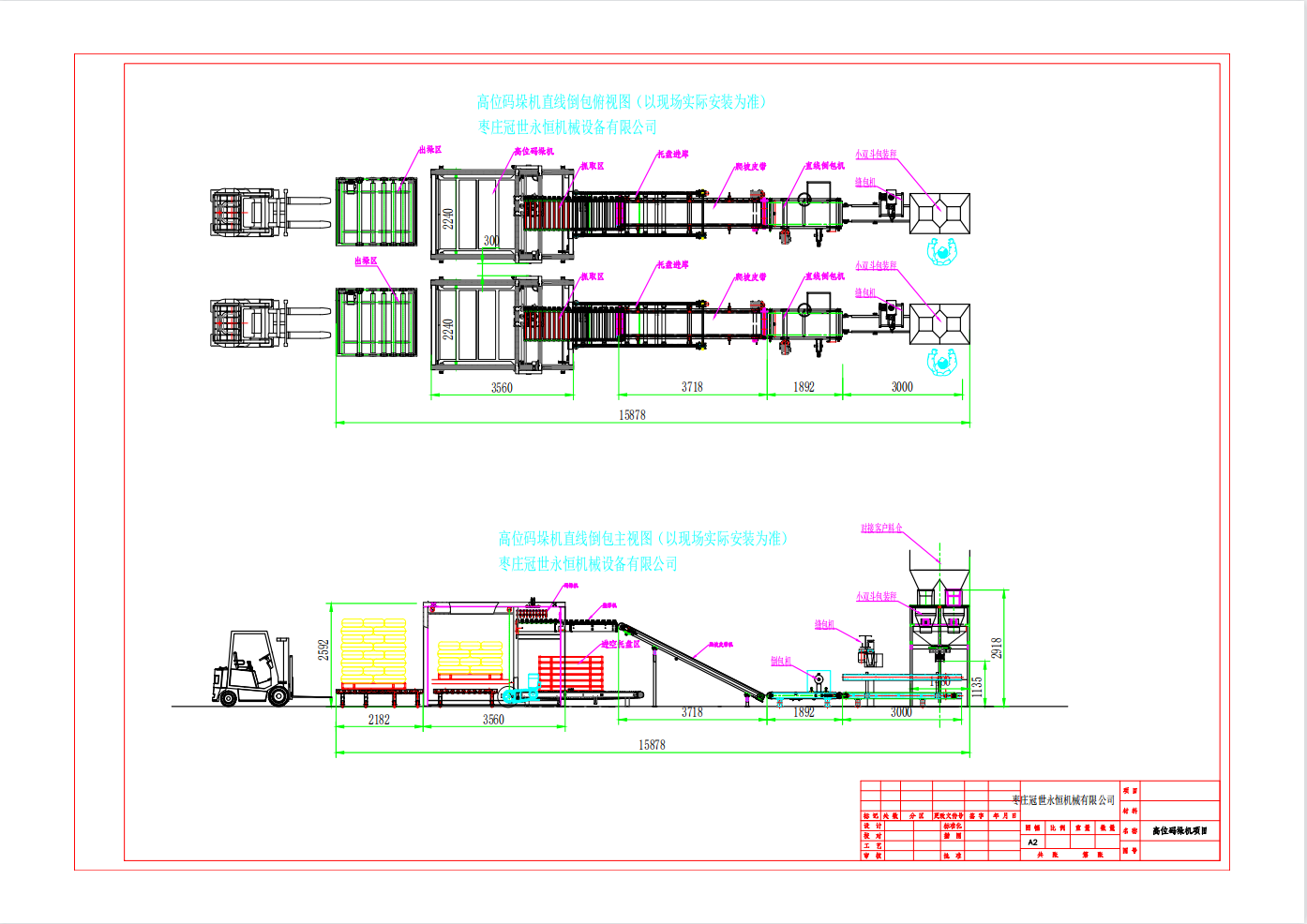

| Model specifications | DCS-Z-S-50 | Equipment height | 2900mm |

| Weighing range | 5-50kg | Power | AC380V 50Hz |

| Graduation value | 10g | Power | 1.3kw |

| Weighing accuracy | 0.2%F、S | Air pressure | 0.4-0.8Mpa |

| Weighing speed | 400-700bag/h | Air consumption | 1m3/h |

Key words:

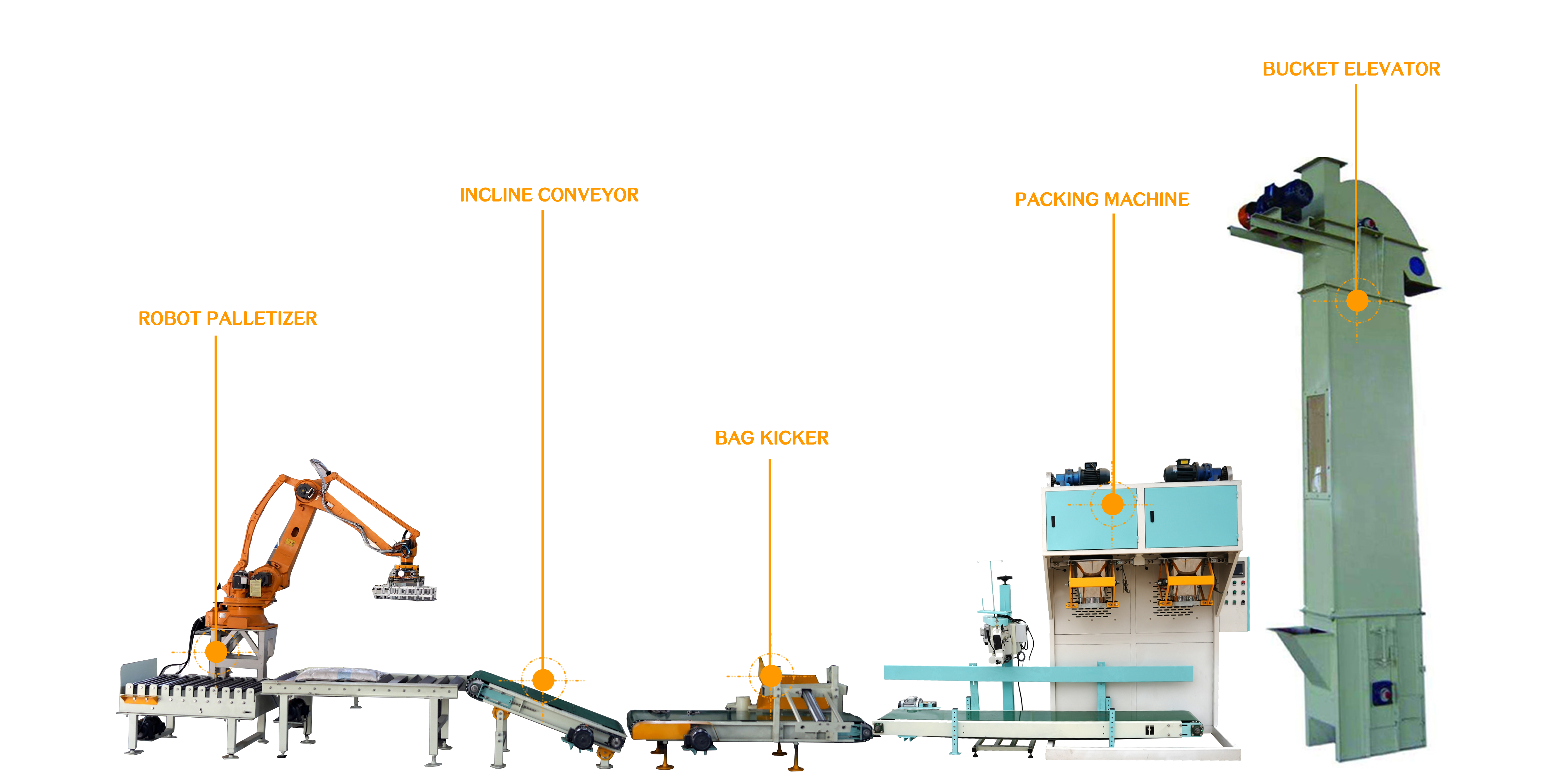

Related Products